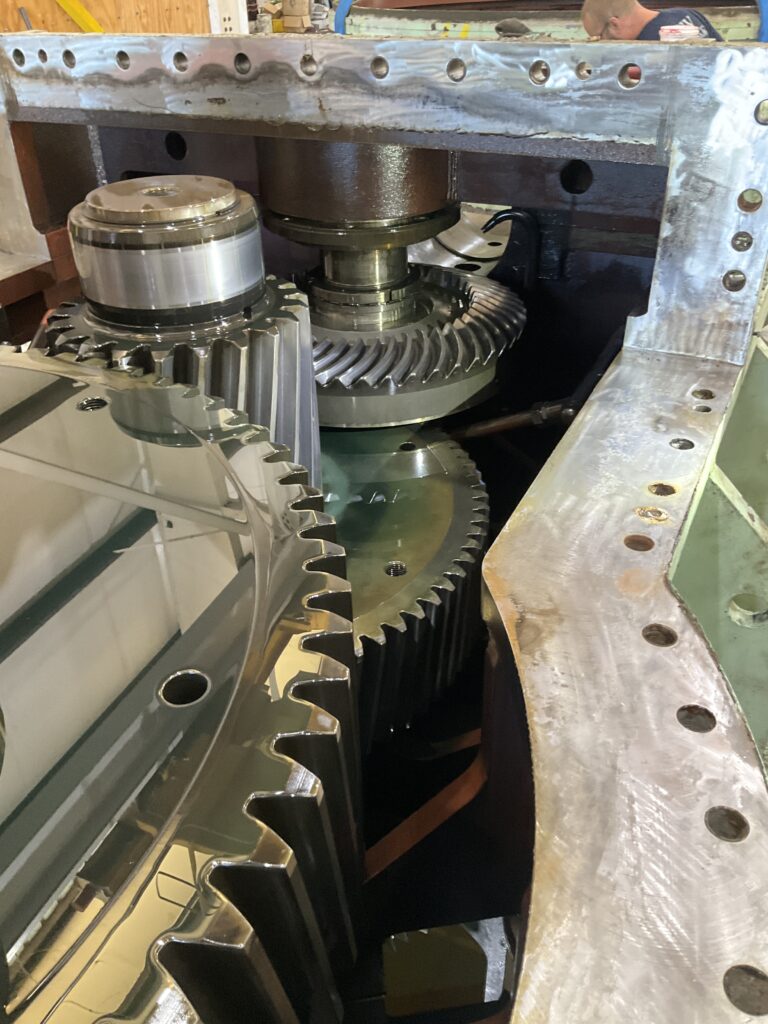

Recently, a cement manufacturer asked us to rebuild its 145,000-pound Flender KMS1100 vertical mill drive during its scheduled 14-day maintenance window. Known for accomplishing the most demanding rebuilds, we enthusiastically accepted the job.

At the outset of the job, our biggest challenge was the weight of the gearbox. It was the heaviest one we’d ever worked on and would require some accommodations.

But weight wasn’t our only challenge. Normally, we would allot a month or more for a repair of this size and complexity. Instead, we had a mere 14 days counting weekends, a schedule so tight it left no room for error, with only a month to prepare. Equally challenging, we wanted to continue serving our other customers without disruption while the giant rebuild was going through our shop. Little did we know the other challenges that lay ahead.

The biggest challenge solved

Even with our current high-capacity cranes and forklifts, we couldn’t lift the entire 145,000-pound gearbox off the trailer. So, we brought in a rigger with two 100,000-pound capacity forklifts to remove it from the trailer and move into the building. Once the gearbox was inside the building, our equipment was able to move it piece by piece. But this was just the beginning of the challenges we had to solve.

Increased repair scope

After disassembly, we discovered further damage we hadn’t anticipated, all of which required extra work to be performed with no additional time allotted:

- Damage from a previous build prevented the hydraulic fit from being used to remove the table. Before the build could proceed, we had to add the task of configuring a strongback and a hydraulic ram that were powerful enough to remove the table without the hydraulic fit.

- The output shaft extension side bearing bore was damaged from a bearing spinning in the bore. We repaired the bore by machining out the damaged section and inserting a sleeve. The housing section weighed 30,000 pounds, which we were able to accommodate in our CNC horizontal boring mill. The machine shop’s resourcefulness enabled us to repair the housing to OEM specifications.

- The customer supplied an OEM Babbit bearing assembly that was incorrect for this style gearbox. Seven of the twelve Babbit pads were missing machining features critical for operation. To remain on schedule, we worked through the night to machine the pads for installation the next morning.

The short timeframe

Luckily, we knew both the customer and Flender and had worked on other Flender products.

“We had looked at the company’s other Flender vertical mill drive the year before,” said Craig Massa, Atlanta Gear VP-Sales. “Having those notes gave us a headstart.”

In addition, Flender sent an experienced German gearbox technician from Canada who supplied us with tech support and drawings that saved us time.

Most of all, according to Taylor Sims, the project’s lead engineer and project manager, the key to meeting the tight deadline was planning.

“Before the gearbox arrived, we formulated a plan of action, purchased some special tooling for disassembly and assembly and decided who would work on it and when,” said Sims. “When the job hit the floor, we knew exactly who would be doing what.”

Minimizing disruptions

At Atlanta Gear Works, emergencies are the norm. We’re staffed, equipped and organised to complete complex jobs on emergency schedules without disrupting other work.

“There were few changes to the processes and people needed to perform this rebuild,” said Sims. “We have standard operating procedures that provide a baseline for achieving positive results across many different operations.”

He added that people on the project were drawn from various departments so as not to deplete any one group. Many of them worked extra hours and even weekends.

“Several of us worked 14 days in a row,” said Sims.

Challenges met — thanks most of all to our people

Most of all, the success of this complex job was due to our amazing people.

“Throughout the project, they were resourceful in solving countless unanticipated problems and stayed committed to a job well done even when it required sacrificing personal time to accomplish it,” said President Jack Conway.