by webadmin

by webadmin

by webadmin

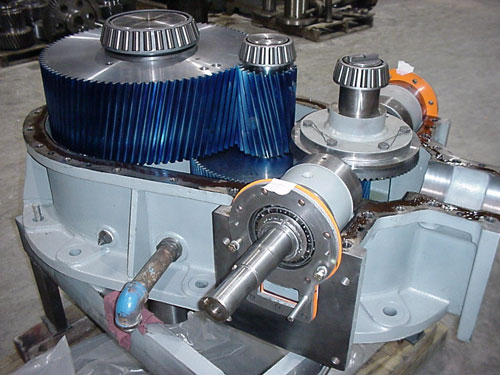

When a gearbox failed at a local wastewater treatment facility, our field services technicians evaluated the gearbox on-site and determined that the high-speed pinion had failed. We were contracted to do the repair. To remove the gearbox from the site, we first...

by webadmin

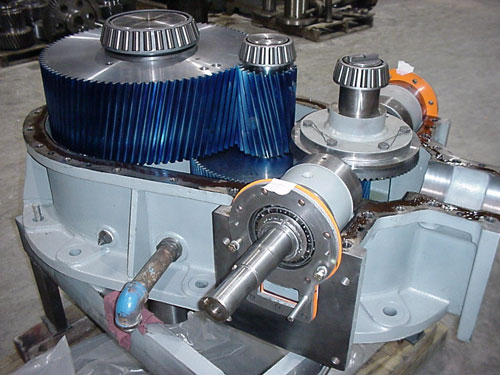

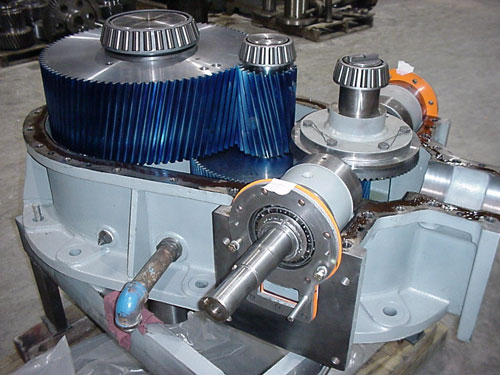

Recently, during an annual gearbox inspection for a large industrial customer, we found that two process-critical extruder gearboxes were in failure mode and needed to be rebuilt. A week-long January outage was scheduled for the rebuild. During our...

by webadmin

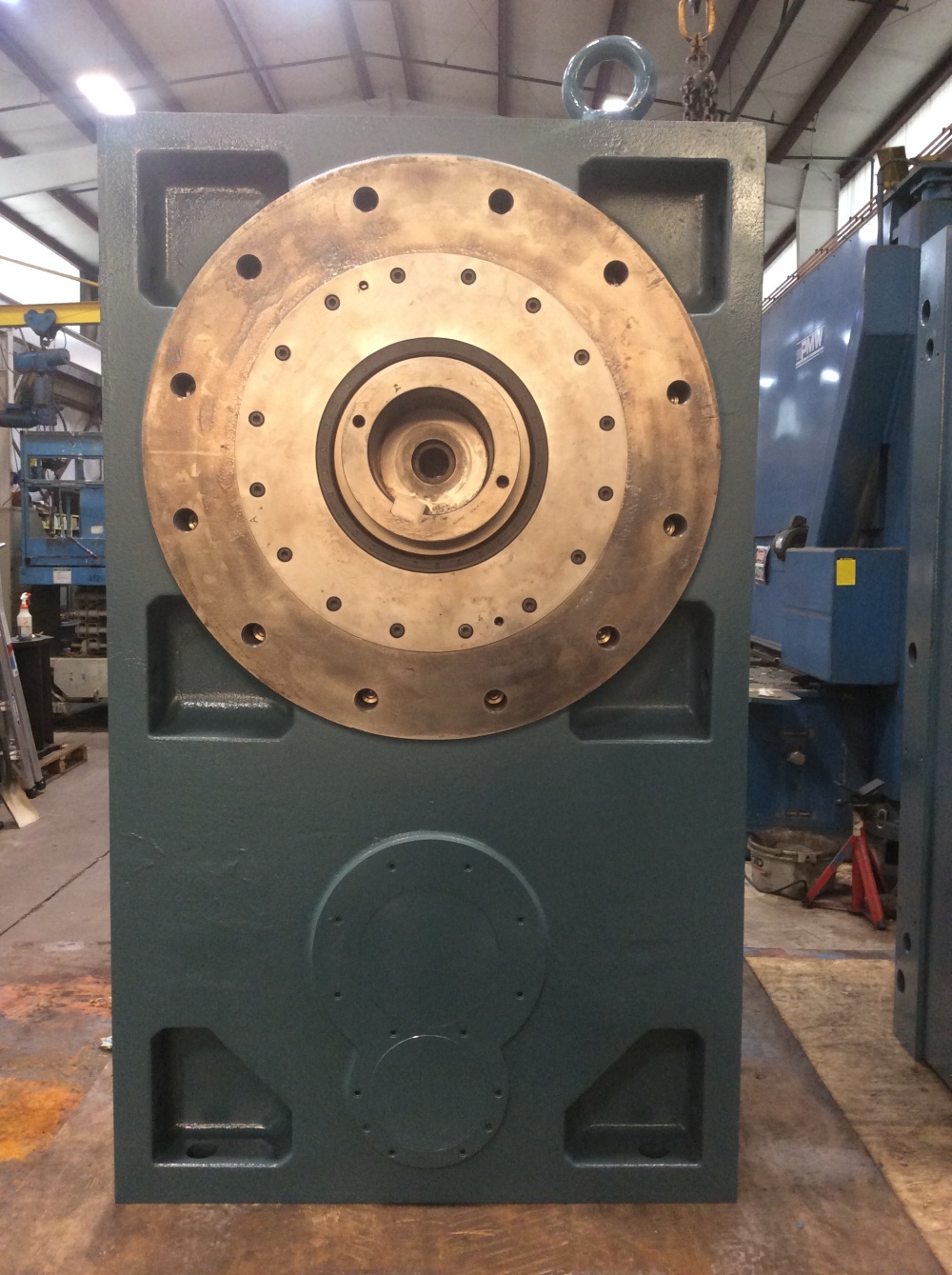

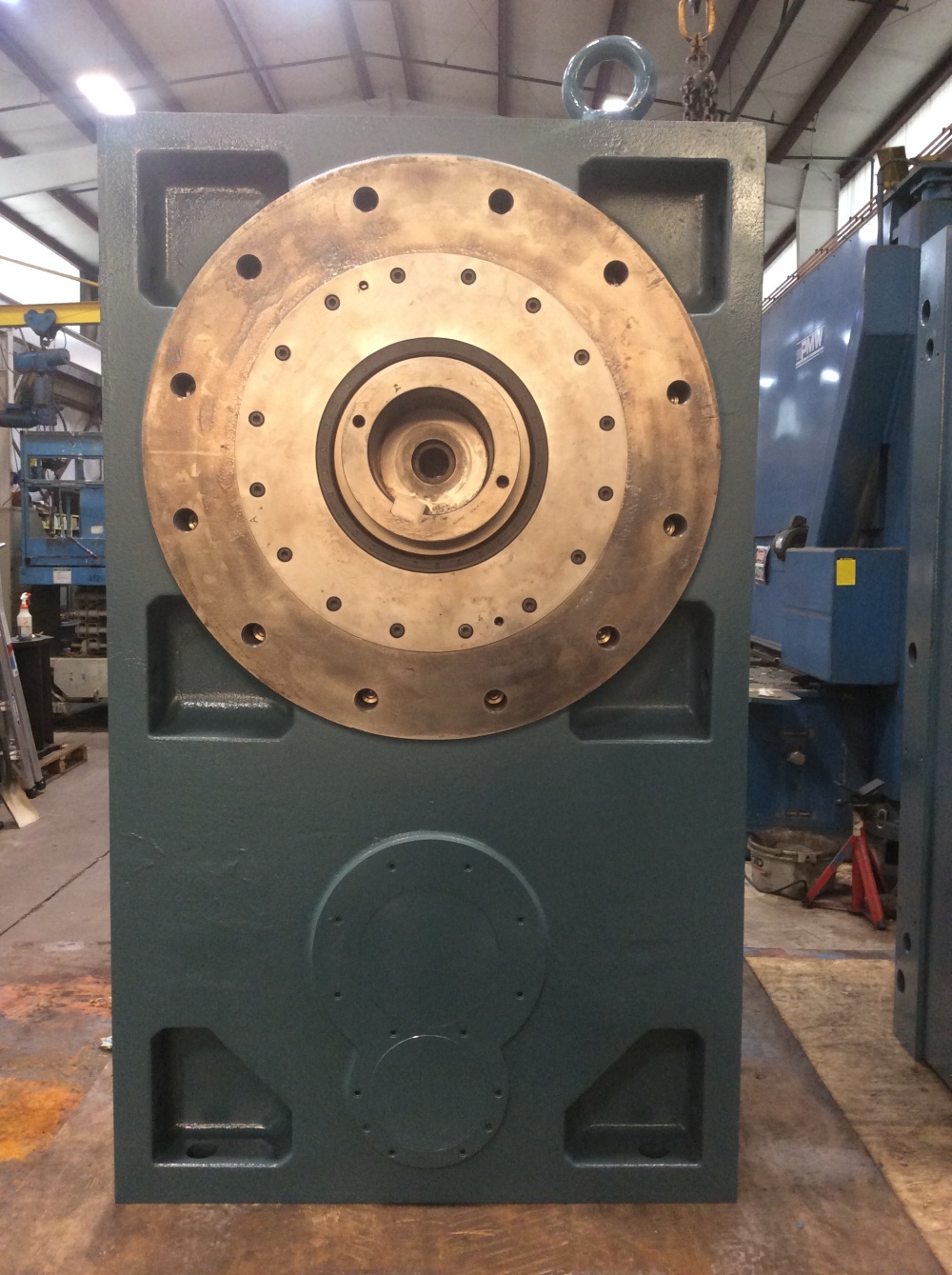

Recently, one of our paper mill customers contacted us about an existing Falk kiln gearbox that was failing. To minimize the customer’s downtime, we acted quickly and were able to secure a qualified surplus gearbox housing. We also manufactured all new gears and...